Genoa New Breakwater

The largest intervention to strengthen the Italian port sector and the deepest dam in Europe

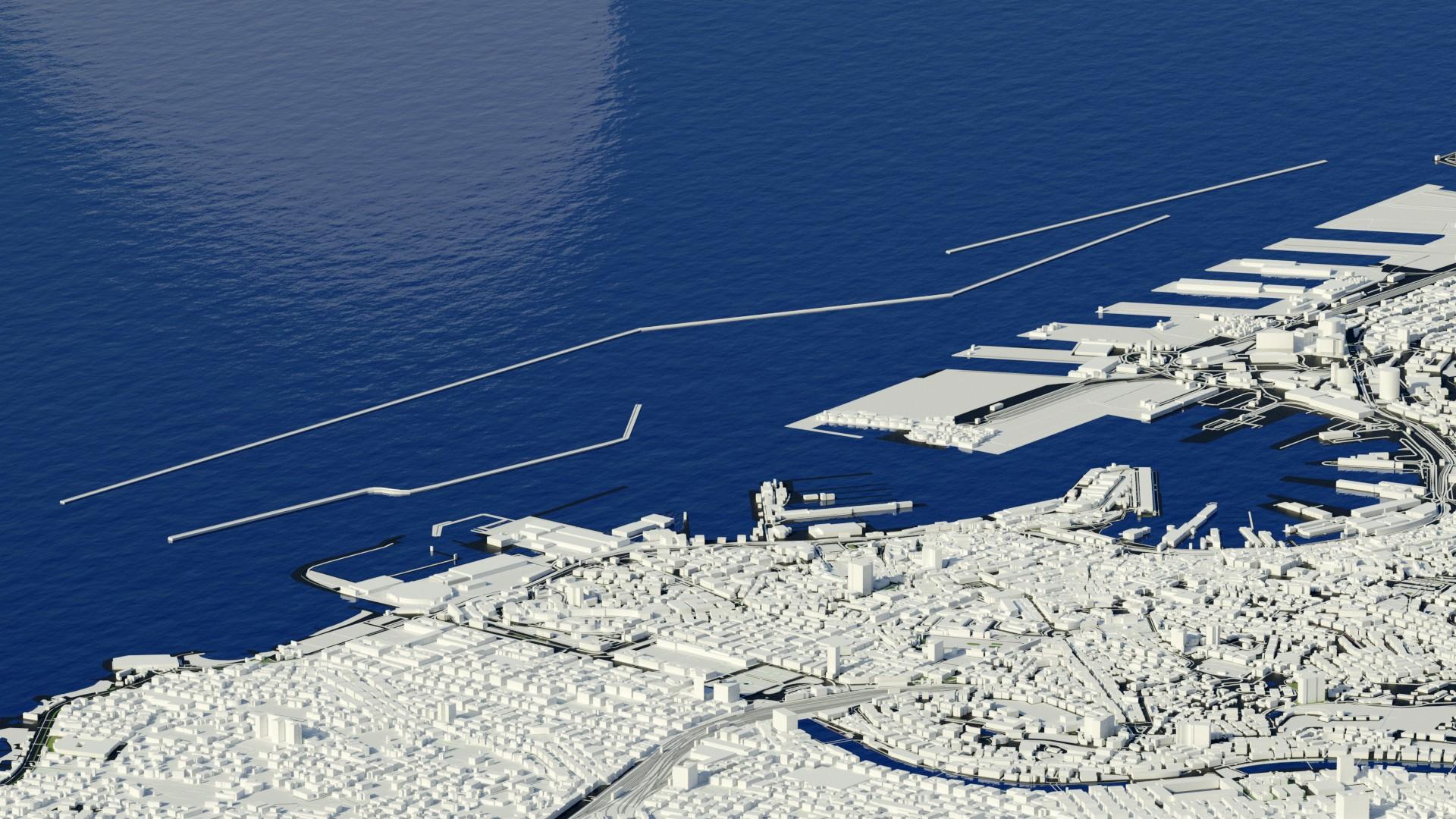

The New Breakwater of Genoa is a unique work in the world for complexity, size, and positive effects on the city and on the country system, as well as being the largest intervention ever for the strengthening of Italian ports.

Thanks to the realization of this work, Genoa is a candidate to become a center of gravity for large ships and a great logistics hub for trade in Europe.

The new breakwater will allow large container ships, over 400 meters long and 60 meters wide, and "World Class" cruise ships to enter the port of Genoa. It will also allow the port to compete with Europe's most important ports, capitalizing on the advantage of the optimal geographical position right at the centre of Asia and the Americas. Genoa in fact is much closer to the large Asian ports compared to ones in the North of Europe: approximately 1,000 nautical miles less that - once the new breakwater is ready - will be a formidable competitive advantage.

Genoa New Breakwater, the deepest in Europe

Genoa's New Breakwater in 3D

La Diga foranea di Genova, la più profonda d'Europa: come sarà costruita e perché - Geopop/Webuild

A look into the depths of the sea: technical innovation and timing

Genoa's New Breakwater is an impressive and one-of-a-kind engineering feat: its foundation will rest on a seabed that reaches a record depth of 50 meters, and in its final configuration will reach an overall length of about 6,000 meters. 7 million tons of rock material will be used to build the basement, on which precast concrete elements will be laid: more than 90 cellular caissons will be placed for the first 4,000 m of the dam.

The caissons will measure up to 33 meters in height (like a ten-story building), 35 meters wide and 67 meters long.

The work will be divided into two phases: the first will end in 2026: it is the new entrance from the east, more than 300 meters wide, which will be builtallowing the maneuvering space for ships to be extended. In the second phase, to be completed in 2030, the widening of the Sampierdarena Canal to a width of 400 meters will be completed, thus increasing the operability and competitiveness of all terminals in the historic commercial basin.

Project's technical data

Genoa New Breakwater: the biggest renewal of the port’s infrastructure on the Ligurian coast in 25 years.

+ + +

Total length, of which about 4,000 m included in Phase A

+ + +

New width of Sampierdarena Channel

+ + +

Maximum depth

New Genoa Breakwater: a unique work from an engineering perspective

Genoa New Breakwater, infographic

The cellular caissons

The New Genoa Breakwater's structure will be divided into modules: i.e. the cellular caissons (named as such due to the fact that inside them they are divided into cells, empty cavities that will be then filled with rock material).

These reinforced concrete giants are as tall as buildings. They are laid one next to the other upon the submerged base to give a shape to the breakwater. The first to be laid measures 21.7 metres in height, 25 in width and 40 in length, while the larger ones will even reach 33 metres in height, 35 in width and 67 in length.

Building the caissons is one of the most complex parts of this work, and on average requires 20 days and engages approximately 50 people.

The caissons are made directly at sea: the metal formwork is placed on a floating platform. The formwork is the perfect splitting image in terms of structural dimensions of the caisson that is to be built. The distancing systems and the metal cage are positioned, and then the first jet of concrete is carried out. When the concrete has solidified, the formwork is raised a few metres and the process is then repeated until the desired height is reached.

Once the caisson has been built, it is moved to the pre-established location where it will be positioned by using tug boats. Then it is sunken, by filling the cells with sea water and once it has been laid on the base, the cells are then also filled with rock material.

The caissons are then completed at sea: it is closed by a superstructure on which the seawall is placed, the most visible part of the breakwater, which has been designed to reduce the effects of the impact of the waves.

The caissons are made by applying sustainability principles when they are built: an innovative concrete mix is used to significantly increase its waterproof quality, while the inside is filled with recycled inert material, also with the material taken from the old breakwater's demolishing.

Le fasi di costruzione dei cassoni della Nuova Diga Foranea di Genova

Nuova Diga Foranea di Genova - I cassoni cellulari: come si costruiscono?

I cassoni della Nuova Diga Foranea di Genova. Come si costruiscono?

Consolidation of the seabed

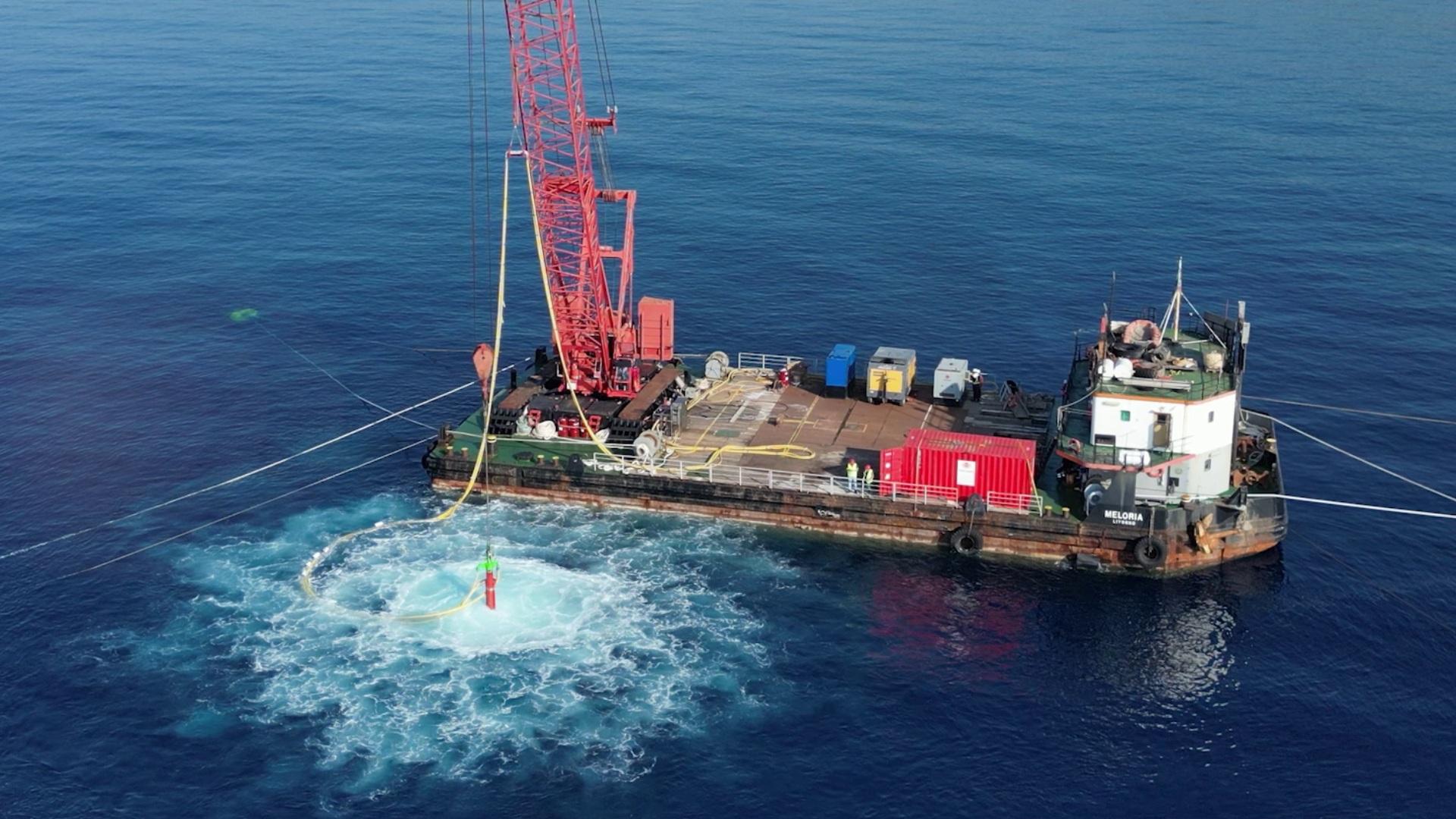

Works include the setting of 70,000 gravel piles measuring between 7 and 12 metres in length to provide stability for the base of the breakwater. Their installation involves 4 pontoons: floating platforms each measuring 600 square metres. Each one has two cranes.

The gravel piles shall support the base built with the use of 7 million tons of rock material (partly taken from dismantling the existing dam, with a circular economy perspective, partly taken from the quarries of Liguria, Piombino, Cartagena (Spain). Material is transported by the ship Maria Vittoria, the bulk carrier Sider Olympia capabel of transporting 40,000 tons of gravel by sea and a third smaller ship too.

The gravel colums will be built using an innovative technique named “Wet Top Feed – Blanket Method”. The technique foresees using a vibrating probe called vibroflot, a needle-like element whose length ranges from 17 to 21 metres. The probe, connected to 40-metre-high cranes positioned on floating platforms (pontoons), is taken down to the seabed, to a previously positioned strata of gravel, to host the the columns that reach 13 metres in height. Vibrating, and by using combined water-air jets, the probe penetrates the seabed creating a tube-like space into which the surrounding gravel flows. As the latter flows, the future columns takes shape and are progressively made more compact.

Videonews Genoa breakwater, launch of the sixth caisson

Nuova Diga Foranea di Genova, in viaggio con la nave Maria Vittoria

Nuova Diga Foranea di Genova, fasi finali di realizzazione delle prime 850 colonne giganti sommerse

Nuova Diga Foranea di Genova, colonne di consolidamento dei fondali marini

Nuova Diga Foranea di Genova, il viaggio della ghiaia da Cartagena a Genova

Genoa breakwater, launch of the fifth caisson

Sustainable just like the sea. The circular economy construction

Environmental impacts of the breakwater's construction are minimized

The innovative construction project involves building a structure designed to protect the docks and port facilities from climate change, a true sea wall.

A solution has been envisaged to reuse almost all the material from the demolition of the old breakwater, with a circular economy way of seeing things, thus minimizing environmental impacts during construction, while concomitantly significantly reducing material transport and disposal, and thus fuel consumption.

Waste materials resulting from the processing of marble quarries will be partially reused, again with a circulatory economy view. As for the concretes used for the construction of cellular caissons, a special mixture has been developed to significantly increase their impermeability.

A number of highly specialized manufacturing plants are to be used simultaneously to make the cellular caissons. Once the caissons are built and waterproofed, they are transported by sea to the project location, sunk and filled with inert recycled materials from the demolition of the old breakwater.

An advanced monitoring sensor system will then allow the infrastructure to be monitored both during construction and after its completion.

Since March 2024, the consortium led by the Webuild Group has partnered with the Acquario di Genova (Genoa Aquarium), to safeguard the sea eco-system in the underwater construction site of the New Genoa Breakwater, and to support an eco-responsible approach in the infrastructure sector. This partnership sees transferring temporarily the sea-life found on the seabed where works are been carried out to the Acquario di Genova, where they will stay until they are then once again put back in the sea when works have been completed.

Genoa New Breakwater. Protecting the sea

Latest Updates on the Genoa New Breakwater

The New Genoa Breakwater is a major engineering challenge with which we renew our commitment to work with Liguria. It is an opportunity to put work back at the center, allowing us to bring back to Italy the know-how and skills of the people who have worked with our Group on some of the world's most iconic water projects.

Webuild and Liguria

Our committment to Liguria: iconic works already completed, strategic projects in progress and a model of collaboration for Italy

You might also be interested in

"Genoa’s new breakwater is the dream of a country that thinks of the future, of our children, of how to be competitive in the world, and of how to build quickly the infrastructure that is needed. This project is not a challenge for Webuild or the Government but for the entire country that must have infrastructure that is innovative and strategic.”

Nuova Diga Foranea di Genova, posa sesto cassone | Webuild